Vacuum forming

Creative Plastics International (CPI) specializes in designing, tooling, and producing high-quality plastic parts. Services include vacuum thermoforming, pressure forming, CNC routing & machining, and 3D printing for various industries. With a focus on precision and customer satisfaction, CPI is committed to delivering innovative plastic solutions that meet unique client requirements.

CPI offers vacuum thermoforming and pressure forming, along with other pre-draw or plug assists such as snap-back forming and billow forming to minimize material thinning and increase pressure, drape forming and matched mold forming.

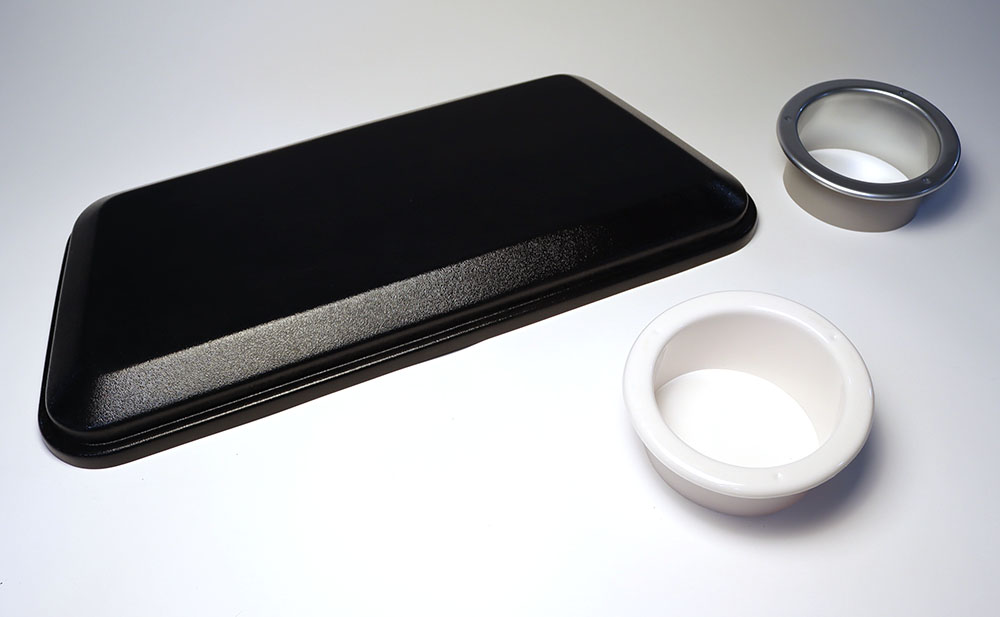

Thermoforming, also referred to as vacuum forming is a method of manufacturing by preheating an extruded plastic sheet or moldable vinyl, draping it over a mold where vacuum is applied to achieve the desired shape. We utilize rotary, shuttle forming processes. The trimmed material is reground and recycled.

Pressure thermoforming is ideal for components that require crisp formed in detail such as labels, logos and printed areas or when a part needs to have various textures on the same surface. Another advantage is the ability to mold in undercuts. This type of forming uses compressed air in order to force the raw material against a mold.

We work with a wide range of materials, including Acrylic, ABS, rigid PVC, PC or Polycarbonate, PE or Polyethylene, PETG, PP or Polypropylene, HIPS or Polystyrene, TPO, Vinyl Clad, and seamless vinyl upholstery composites. Each material is carefully chosen for its specific properties, ensuring that our products meet the unique requirements of our clients.

Typical Applications Include:

- Specialty automotive: interior trim pieces, headliners, dash panels

- Sport & utility vehicle: vinyl seat covers / skins, plastic caps

- Marine & recreational vehicle:storage tubs, livewell compartments

- Consumer products: refrigerator liners, shower surrounds

- Retail and display: casegood bins, tissue/napkin dispensers

- Packaging: protective carrying cases, trays, bins, plastic pallets

- Healthcare: vinyl upholstery for stools, chairs & exam tables, operating room equipment housings, hospital bed surrounds

- Seating: backpanels, adjuster covers, armcaps

- Sound proofing / noise control: diffusers

- Bezels, panels, guards & housings for industrial, electronic, sport and leisure equipment

Products and Services

Some complex cut to size part designs are better suited for 3D Printing .

CNC Routed & Machined Plastic

5-axis CNC Routing is robotic trimming that generates a path for part trimming, milling and drilling.

Vacuum Thermoformed Plastic

Vacuum thermoforming and pressure forming, along with other pre-draw or plug assists such as snap-back forming and billow forming.

3D Printed Parts & Services

3D printing is a highly versatile and powerful tool that can be utilized in various manufacturing applications.

CPI Case Studies

Case studies showcase examples of manufacturing issues solved with CPI manufacturing processes.